Yupcera

Uwima All in One Mill

Uwima All in One Mill

Verfügbarkeit für Abholungen konnte nicht geladen werden

Niedriger Lagerbestand: 10 verbleibend

-

- CNC system suitable for all materials

-

Zirconium, wet and dry

Wax

PEEK

Titanium

CrO2

Abutments

Preforms

Disilicate

- [ 24/7 first level support aus Europa]

SHIPPING

SHIPPING

24/7 SUPPORT

24/7 SUPPORT

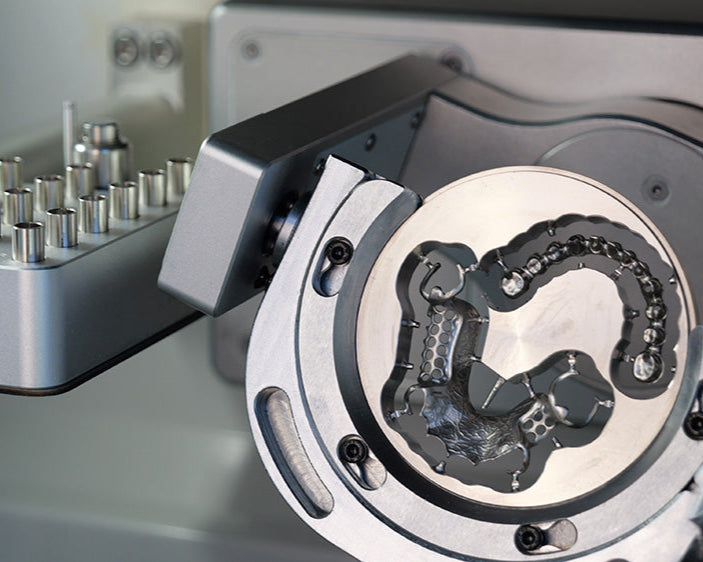

INNOVATIVE MULTI-FUNCTION FIXTURE

Versatile milling for lithium disilicate, titanium discs, titanium column, and soft metals with ease

HIGH PRECISION AND STABILITY

Spindle speed: 60,000 rpm

Precision: ±0.01mm

AUTOMATIC TOOL CHANGE & AUTOMATIC CALIBRATION

Save time, simplify operations and improve work efficiency

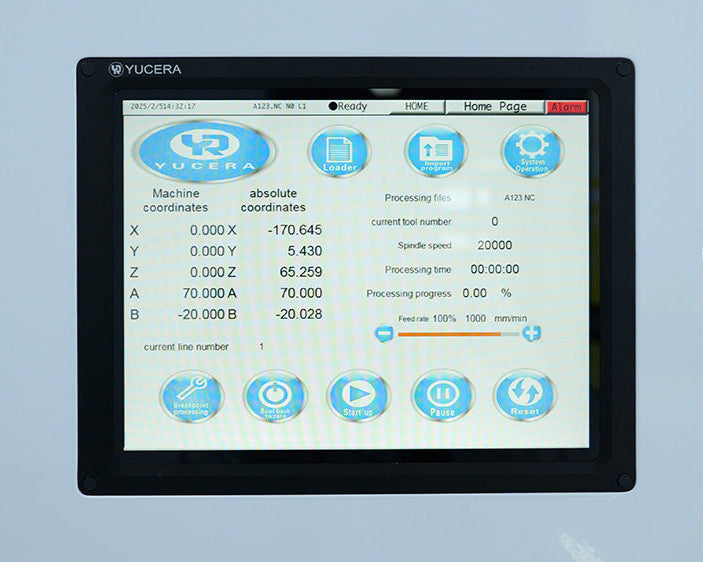

SMART DIGITAL TECHNOLOGY

Resume when interrupted to eliminate work duplication.

Unlock unparalleled efficiency and stability with YCR 8S right now!perations and improve work efficiency

A ONE STOP SOLUTION.

TECHNICAL DETAILS

GENERAL

Fields of application:Wet Milling

Materials: Titanium disk, PMMA, Lithium Disilicate, Titanium column

Indications:Veneers, inlays, onlays, full crown, simplant-based restorations

BASE SYSTEM

1. High precision

① High-precision ball screw and P3-grade grinding guide rail, fine grinding processing

② Full servo control system, realizing closed-loop control of position, speed and torque

③ ±0.01mm processing accuracy

2. Strong stability

① Adopting international standard full Meehanite cast iron, machine tool cast iron integration, with high rigidity and more stable body

② Bottom Foma wheel design, can bear the bottom weight and reduce vibration

3. Humanized design

① Excellent and simple human-machine interface, easy to understand, only one-button operation, more friendly design

② Processing status indicator light belt design, better understand the machine operation status

4. Automation and high efficiency

① 16 automatically switchable tool magazines to meet the processing of various materials

② Automatic calibration function, so that the machine maintains the original accuracy

5. All-round service is more assured

① Core parts are not damaged by human factors for 14 months

② Professional after-sales team 24 hours service

6. Personalized customizable function

Optional dry and wet intelligent switching module, vacuum cleaner, air pump, needle, etc. to meet diverse needs

ENVIRONMENTAL CONDITIONS

Operating temperature:Between 10℃ and 35℃

Air moisture:Max.80%(relative), non-condensing

SPINDLE

Spindle speed: 0~60000rpm/1.8KW

Travel range: X/Y/Z: 230-120-100mm

Processing accuracy: ±0.01mm

Drive: Full servo motor

AB axis working angle: A: 360° B: -95°~+30°

2 types of fixtures

Suitable for disc, base, block processing

APPROVALS

All models:CE, VDE North America model:UL, FCC

DIMENSIONS & WEIGHTS

Dimensions(W/D/H):595*760*1650mm with open flap and drawer

Weight:360KG

AUTOMATION

Automatic tool magazine

16 tool magazines, automatic switching

Double-layer filtration system

25L water tank capacity, easy filter replacement

CONNECTION REQUIREMENTS

Required air pressure: 4.5-7.5bar

Power supply: 220-230V AC, 50/60HZ

Power: 2.5KW

Compressed air flow: about 120L/min

PROCESSING MODES

5-axis linkage, Wet milling

Processing time:Full crown < 15 min, 3-unit bridge < 30 min

Processable material thickness:10-30 mm